Automotive logistics: how we can help

The automotive logistics process tends to be complex. It requires original equipment manufacturers (OEMS) to carefully plan each stage of the movement of vehicles, parts or supplies to reduce the risk of complications.

In this blog post, we will look at the process of automotive logistics and the benefits of outsourcing these services.

What is automotive logistics?

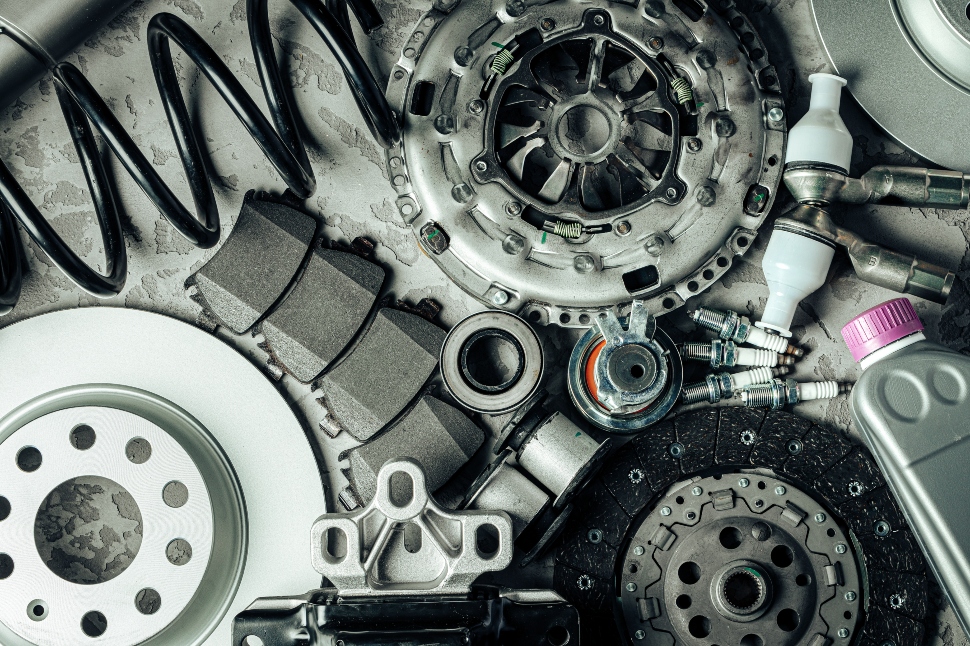

Automotive logistics is a specialised approach to the planning, coordination, and execution of various activities associated with the distribution and management of products via an automotive supply chain.

What is the importance of efficient automotive logistics?

In the automotive industry, a smooth logistics process is critical for planning the most efficient transportation routes, ensuring the timely delivery of components to assembly plants, managing inventory levels, and delivering finished products to dealers.

The complexity of the automotive supply chain, with its vast network of suppliers, manufacturers, distributors and customers spread across multiple regions, is what makes efficient logistics practices in the industry critical.

Successful logistics operations help automotive companies reduce costs, reduce lead times, improve inventory management, maintain product quality, and increase customer satisfaction.

Benefits of outsourcing automotive logistics

Outsourcing your logistics can provide additional benefits to your business. Here are ways in which you can benefit from outsourcing your automotive logistics to a third-party (3PL) provider.

-

Benefit from specialist expertise

Whether it’s production logistics, spare parts inventory management, or sea freight, choosing a company with industry expertise is the most effective way to ensure efficient, smooth processes are followed. Partnering with experts in the automotive logistics field is critical for navigating international regulations, customs requirements, and health and safety compliance.

Expert knowledge is especially useful when transporting specialist vehicles such as motorcycles or military vehicles, which require cautious handling.

Experienced logistics companies will understand the meticulous planning, consideration, speed and accuracy required to successfully move automotive products, parts, and components throughout the supply chain. This makes these companies more efficient at completing and adept at overcoming obstacles on the job.

-

Cost reduction

Undoubtedly, one of the most significant advantages of outsourcing logistics services in the automotive industry is the reduction of costs associated with managing these logistics processes.

Transporting automobile parts, especially those that are heavy or oversized, can be expensive. Carriers frequently charge surcharges on packages that exceed weight limits, such as 70 or 150 pounds, and even oversized boxes, regardless of how much they weigh, will be subject to dimensional weight pricing. A 3PL provider will have a network and partnerships with transportation providers, allowing them to negotiate better rates for both shipping and warehousing services.

Furthermore, they will save you money on the costs of maintaining your own logistics infrastructure and workforce. Internal logistics would involve investing in a vehicle fleet and bearing the costs of its maintenance, as well as hiring and training drivers, dispatchers, logistics, fleet management tracking software, and operational costs, in addition to your current business expenses.

Reputable 3PLs will also be aware of and adhere to changes in current transportation regulations and legal obligations. A logistics provider can help you reduce the risk of receiving fines for overloading or failing to follow regulations.

-

Scalability and flexibility

The automotive market is highly dynamic, with fluctuating demand and production volumes.

Another major advantage of logistics outsourcing is the ability and resources these companies have to respond to fluctuating volumes. This is relevant not only to business growth but also to seasonal fluctuations, business decline and unforeseen crises like the COVID-19 pandemic that lead to raw material shortages and supply chain issues.

Businesses that partner with a 3PL provider can easily scale their operations for any of these reasons. Whether it’s expanding or decreasing storage capacity, increasing order fulfilment capacity, or entering new markets, outsourcing logistics enables businesses to change their operations according to market demands without major disruptions.

This enables automotive companies to better manage their resources and respond quickly to consumer demand, resulting in smoother and more responsive logistics management that benefits the entire supply chain.

How OSE can help

At OSE, we work as integral supply chain partners with several high-value companies in the automotive industry, demonstrating our practical and value-added approach to supply chain management.

With our extensive industry experience, we understand the importance of meeting urgent requests from dealers and customers. That is why we provide tailored, time-critical solutions designed specifically for the automotive industry.

Automotive delivery times vary depending on the supplier. As a result, our team will work to ensure the flexible and timely delivery of critical automotive parts and components.

Read our case study on an automotive logistics solution we completed for Cramlington Precision Forge here.